What is EDM?

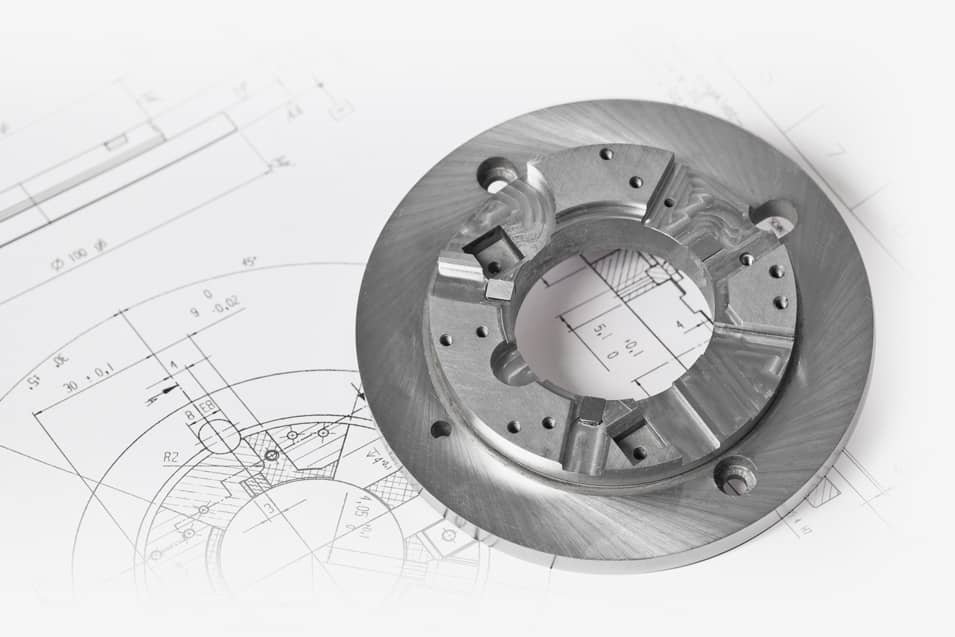

EDM, short for Electro Discharge Machining, is a process where a thin wire serves as a conductor for electrical discharges. These discharges produce small sparks that etch away material, enabling cutting with utmost precision.

This process, also known as 'spark machining', is particularly effective for cutting hard or difficult-to-machine materials. It is akin to precise jigsaw cutting, but whereas in jigsaw cutting the wire moves up and down, in EDM the wire passes through only once.

What is EDM Used For?

EDM wire is widely used in various industries for the precise machining of materials such as steel, carbide, aluminum, and copper.

The precision of EDM makes it ideal for the production of complex parts in sectors such as aerospace, medical technology, and precision mechanics.

EDM Wire

Wire EDM is one of the applications of EDM. Here, a thin wire is used to cut out complex patterns and shapes.

This method is suitable for creating detailed outlines and is primarily used in the ophthalmology and watchmaking industries.

EDM Drilling

EDM drilling is another variant of EDM, where a hollow tubular electrode is used to drill precise holes in various materials.

This technique is ideal for creating starter holes or intricate internal structures.

In Which Markets Do We Succesfully Apply it?

EDM is successfully applied in markets that demand high precision and quality. We produce, among other things, small, precise medical instruments.

But EDM wire is also used in the watchmaking industry.

The Advantages of EDM Wire Technology

Due to the absence of direct contact between the tool and material, there is no risk of mechanical deformation. This makes EDM wire ideal for processing very hard or brittle materials. Additionally, the precision ensures consistent quality, even with the smallest dimensions.

Why Choose EDM at Lasertec

At Lasertec, we specialize in providing high-quality EDM services. Our advanced machinery and expertise enable us to meet the specific needs of our clients. We deliver the highest quality for a wide range of applications.

EDM wire technology is indispensable for modern production. It offers the ability to work with unprecedented precision. At Lasertec, we understand the unique demands of this technology and are committed to providing a fitting solution for every challenge.

Laser cutting is a technique that offers precision and versatility. We are able to meet the complex and varied needs of our customers.

For more information about our EDM capabilities or any of our other services? Please contact us at

+31 180 644 744

or fill in the contact form.

Process combination

Through an intelligent combination of process and know-how, we exceed the limits of what’s possible

Competences

Thanks to our years of continuous development, we offer many possibilities within our company. The laser today represents a strong and reliable process that can be adapted to different applications. Most laser capabilities are accessible within the same process. Imagine: texturing a surface, engraving your logo, and cutting parts with a single laser.

Numbers

Our success would not be achievable without a significant number of different laser

production units, years of experience and most importantly, a strong team.

More than

25

Laser production units

More than

37

People

More than

27

Years experience

Contact Us

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | Lasertec