Mechanical Bending

Leading in Mechanical Bending

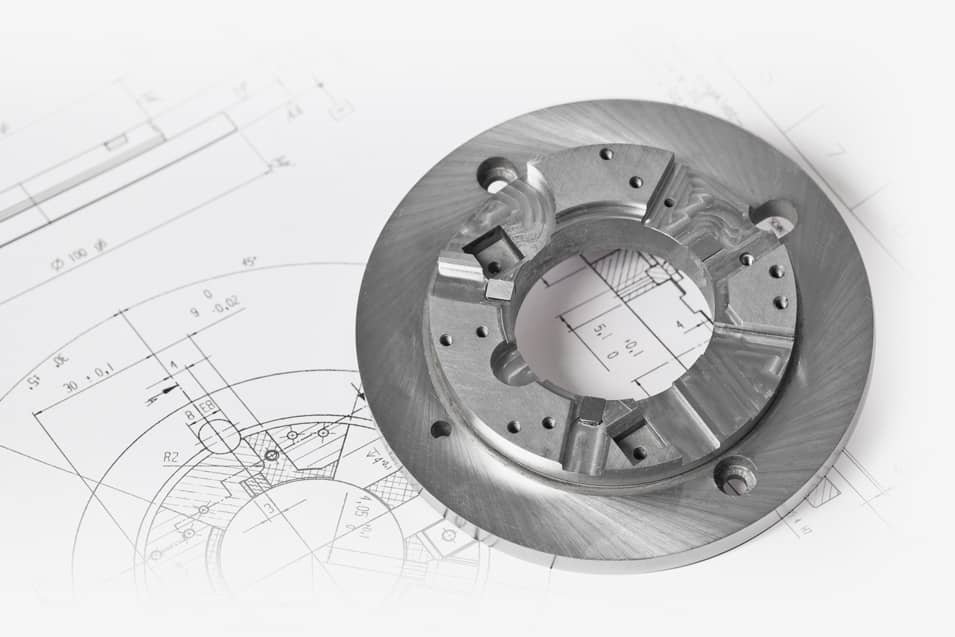

In the world of metalworking, mechanical bending is a specific technique. It involves deforming metal into complex parts, mainly applied in machine construction.

Think not of large machines, but rather of an electron microscope, machines in the medical world, and the semiconductor industry.

What is Mechanical Bending?

Mechanical bending is also known as cold deforming or high-precision small bending work. It's a process where metal parts are formed without heat treatment, often using sheet or foil material from 0.02 mm to 1.5 mm thick. Due to the fineness of the materials, the end products are so small that they can fit inside a drinking cup.

The technique demands a high degree of precision and is therefore difficult to automate. Mechanical bending is almost always manual work.

What is Mechanical Bending Used For?

As the term implies, high-precision small bending work is used when complex, small parts need to be made. These parts are often used in machinery for various industries. We make components, for example, that shield heat, enable mechanical movements, or conduct electricity in refined equipment.

Micro bending is also applied in the watch industry, for making tiny springs.

How We Combine Multiple Services with Mechanical Bending

Our clients' challenges often involve more than just applying micro bending. We almost always combine this with one of our other applications, such as laser cutting or laser welding. This results in seamless production of parts that exactly meet our clients' requirements.

We collaborate with specialized partners like LTJ in Wiege, who carry out the small bending work for us. We focus on preparing the material, such as cutting, after which our partner handles the cold deforming. After receiving the formed material, we then complete the finishing.

The Advantages of Mechanical Bending

Since no heat is used in the cold deforming process, the mechanical properties of the metal remain intact, which is a significant advantage. This results in parts with high precision and reliability, incredibly important for the complex applications for which the parts are made.

Additionally, the precision of the process allows for the realization of very complex shapes.

Why Choose Mechanical Bending at Lasertec

At Lasertec, we understand the complex needs of our clients. We collaborate with you to find a solution. Our partnership with specialized partners ensures that every project is executed to the highest standards. We guarantee that each part perfectly meets our clients' requirements, from concept to final product.

In mechanical bending, precision, craftsmanship, and technology converge. Lasertec embraces this challenge and strives to provide excellence in every phase of the production process.

For more information about our Mechanical Bending capabilities or any of our other services? Please contact us at

+31 180 644 744

or fill in the contact form.

Process combination

Through an intelligent combination of process and know-how, we exceed the limits of what’s possible

Competences

Thanks to our years of continuous development, we offer many possibilities within our company. The laser today represents a strong and reliable process that can be adapted to different applications. Most laser capabilities are accessible within the same process. Imagine: texturing a surface, engraving your logo, and cutting parts with a single laser.

Numbers

Our success would not be achievable without a significant number of different laser

production units, years of experience and most importantly, a strong team.

More than

25

Laser production units

More than

37

People

More than

27

Years experience