Laser Ablation

Leading in micro Laser Ablation

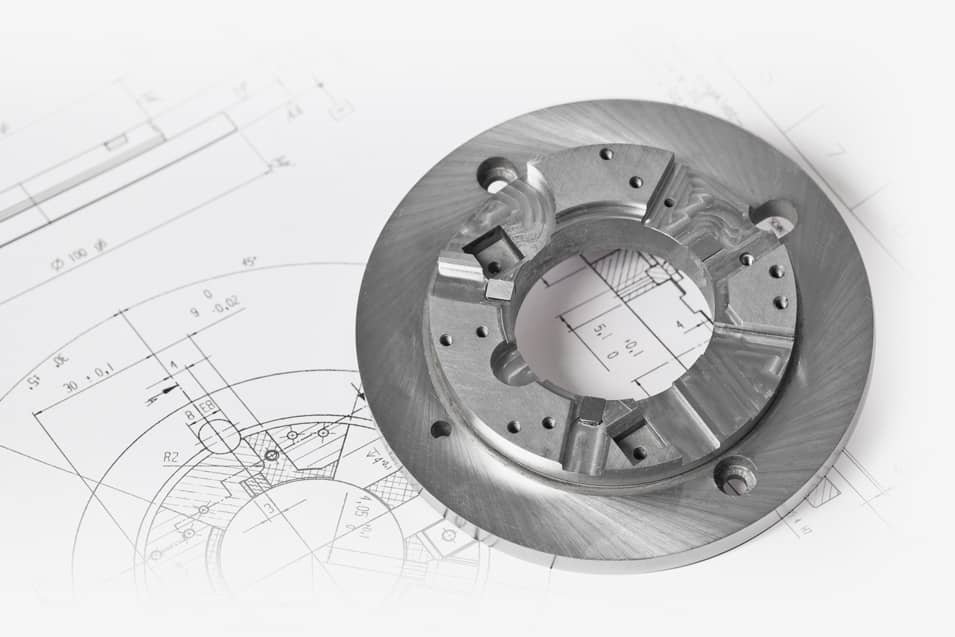

Laser ablation is a special technique in which laser technology is used to process materials with unparalleled precision. Whether it's microlaser ablation for extremely fine details or more large-scale applications, laser ablation offers many possibilities that far exceed traditional methods.

What is Laser Ablation?

Laser ablation is a process where material is removed layer by layer using short pulse lasers. This method is unique because the material does not melt; it is directly transformed from solid to gas.

You can compare it to removing one marble from a jar without the other marbles moving - that's how precise laser ablation works.

What is Laser Ablation Used For?

This method is used in sectors where precision and minimal heat input are very important or desired. Think of applying patterns to micro-instruments in ophthalmology or creating components for electron microscopy. This technology is also used in the semiconductor industry, where accuracy is of great importance.

How is it Different from Laser Drilling?

In laser drilling, we melt material and then blow it away, generating a lot of heat. In the case of ablation, there is little to almost no heat development. This makes it ideal for applications where the integrity of the material must be preserved.

With both methods, a hole can be made in material, but with ablation, this is done with minimal heat input. However, laser drilling is much faster because we do not have to remove layer by layer.

In Which Markets Do We Succesfully Apply it?

At Lasertec, we broadly apply laser ablation. The sector that is most imaginative is the medical sector. Here, we develop tubes of 0.4 mm which then contain an ophthalmic instrument. In addition, we develop components for electron microscopy and for the related world.

The Advantages of Microlaser Ablation

Because microlaser ablation is so precise, it is possible to create extremely small and complex shapes with an accuracy up to the µ. This technique is particularly suitable for fragile applications where any microscopic deviation can have a significant effect. The precise tolerances, often up to +/- 0.001 mm, make it an indispensable method in precision engineering.

Why Choose Microlaser Ablation at Lasertec

At Lasertec, we specialize in microlaser ablation, where we continuously push the boundaries of technology. We are able to process materials with a precision comparable to removing a few microns - for illustration, one micron (µ) is about 1/35th of the thickness of a human hair. We can remove 150 to 160 layers of the thickness of a human hair, which underscores the precision and refinement of our work.

It's all about the long-term, consistent production of high quality for us. We focus not only on creating an accurate product but also on ensuring the consistency of that product over time. This means that we ensure our customers receive exactly the same high-quality result weekly, monthly, and annually.

Want to know more about laser ablation or any of our other services? Please contact us at

+31 180 644 744

or fill in the contact form.

Process combination

Through an intelligent combination of process and know-how, we exceed the limits of what’s possible

Competences

Thanks to our years of continuous development, we offer many possibilities within our company. The laser today represents a strong and reliable process that can be adapted to different applications. Most laser capabilities are accessible within the same process. Imagine: texturing a surface, engraving your logo, and cutting parts with a single laser.

Numbers

Our success would not be achievable without a significant number of different laser

production units, years of experience and most importantly, a strong team.

More than

25

Laser production units

More than

37

People

More than

27

Years experience

Contact Us

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | Lasertec