Why has laser welding appealed to the medical industry?

Laser welding is the most accurate welding process available today with the least amount of heat. This procedure allows the assembly of thin parts of less than 1 mm without any deformation.

Concept of laser welding and how it works

Laser beam welding procedures produce high quality, high strength welds without porosity. The process can be automated for use on a variety of materials, especially thin parts. Metals and alloys that are typically laser welded include steel, aluminum, titanium, copper, gold and others.

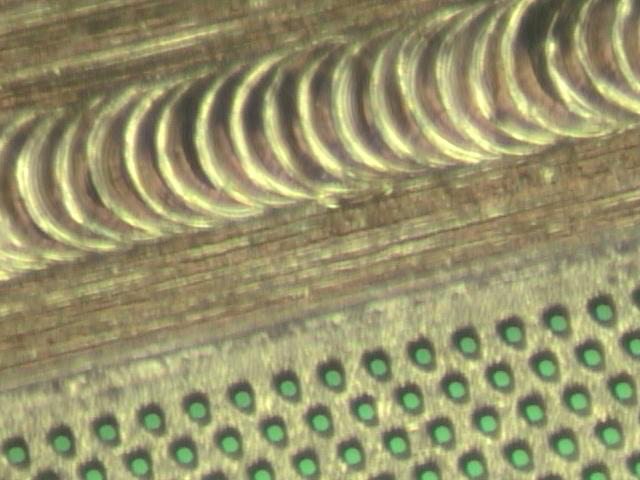

In laser welding, no external material is used. The welding is therefore performed solely by melting the areas to be welded. The high energy supplied makes it possible to reach, and even exceed, the melting temperature of the material. It is important to know that the use of an inert gas such as argon or helium in the welding process prevents the formation of oxygen bubbles during the liquid phase of the material. This reduces the porosity during welding. By using other types of focusing mirrors, such as the double focus mirror, it is possible to control both the penetration depth and the width of the laser beam. Thus, laser technology allows for different geometries with spot or continuous weld seams.

For what type of project?

In general, any industrial project requiring the welding of parts can use laser technology. In particular, the markets that use this technology the most are the automotive, aerospace, medical and watchmaking industries. Some of the machines used in these fields manufacture parts that require high quality welding. Among these applications, high and medium volume production of sheet metal parts, automotive parts on chassis, household appliance parts, aeronautical parts made of aluminum or nickel-based superalloys, welding of food processing and packaging machines, medical, surgical and dental instruments.

The great advantage of using laser welding machines is their great versatility. Among the materials that we can laser weld :

- stainless steel

- aluminum

- gold

- silver

- platinum

- nickel

- titanium

- some polymers

With this wide variety, laser welding allows great precision and efficiency, especially for small parts.

Laser welding professionals

Laser welding has certain advantages over other more conventional techniques. High precision, high welding speed, low heat transfer and little deformation of the welded surface are some of the advantages of laser welding, allowing high quality and durable welds. Therefore, laser welding is the key to accelerate and improve many processes in industry.

Nevertheless, it is important that it be done by a professional. Lasertec relies on its well-trained and certified welding personnel. They are able to perform, with great precision, the different welding processes using equipment and systems developed in-house. They use innovative solutions that improve productivity, quality and production costs for companies.

The medical industry and its needs in laser welding

In the medical industry, the application of laser welding can be used in the manufacture of various equipment, such as scanner and diagnostic equipment, as well as machines for suture production.

Our systems used are also capable of producing laser spot (single pulse) and seam (multi-pulse overlap) welds, including hermetically sealed laser welds. We also have a range of fiber laser welding systems for more precise welding with smaller spots. Pacemakers, defibrillators, guide wires, catheters, hearing aids, orthodontic appliances, prosthetics and surgical tools are just a few of the many successful applications of medical devices created using our laser welding systems.

The laser welding revolution in the industrial world

Although laser welding technology was originally applied to the manufacture of military tanks, it has gradually become applicable to various industrial fields, particularly in the medical industry. Today, laser innovation allows for precision processes that guarantee stability, repeatability and traceability of production data. Clean, fast, flexible, reliable and suitable for clean rooms, the laser systems used by medical industry professionals allow the production of safe, hygienic and hermetically sealed welds between plastic or metal components, without chemical additives, foreign bodies or particular contamination.

Conclusion:

Today, this evolution of laser welding is considered to be the independent innovation that is the source of business development within companies. Lasertec puts its long experience at your disposal to make your most complicated projects a success.

Contact Us

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | Lasertec